Meet the new generation of automatic nailer for pallet production!

The Pneumatico AT-3000 is an advanced automatic pallet nailer designed for maximum efficiency and intuitive operation. It offers the flexibility of producing different types of pallets on one machine by changing the template.

Technical specifications:

Capacity:

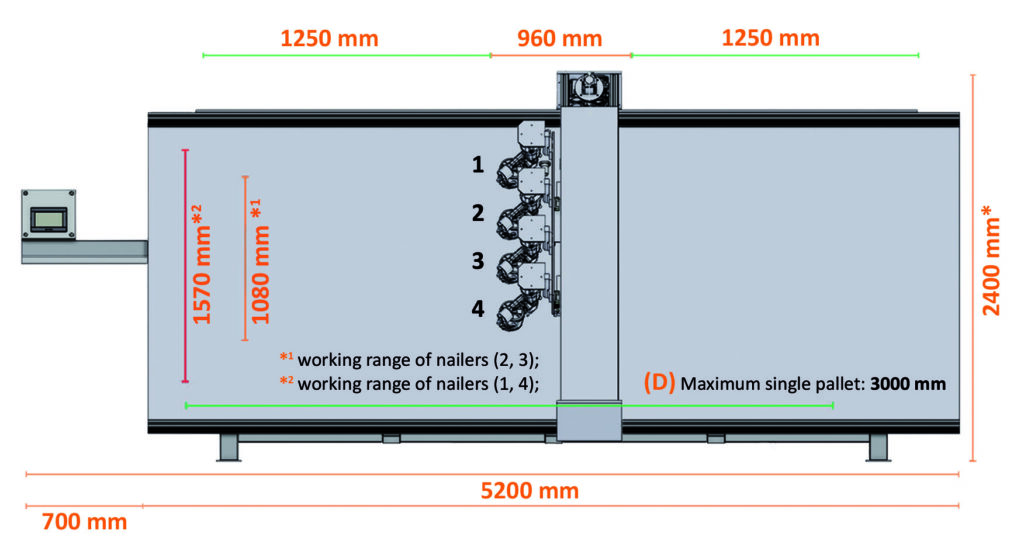

Machine Dimensions:

Working Area:

Working range of nailers:

|

Advantages of Pneumatico AT-3000:

- Ability to produce two different pallets on the right and left side.

- Compact design – the controller is integrated into the machine.

- Constant monitoring of the air pressure level in the system guarantees correct nailing.

- Ability to set the speed and acceleration of the nail down module to suit your needs.

- Memory for up to 900 pallets.

- Upgradable with a pallet pick-up robot.

- Counter for manufactured pallets.

- Nailer magazines equipped with nail presence sensors.

- Ability to use PAUSE/ START button without interrupting the cycle.

- Control panel in 3 languages: ENG, PL, DE.

- Safety switches on the left and right side of the table for the fastest possible response in case of danger.

- Safety strips that immediately immobilize the machine in case the operator approaches the working field of the nail down module.

1. What types of pallets can be produced on the AT-3000 machine?

The AT-3000 machine allows for the production of a very wide range of pallets – disposable, industrial and EUR/EPAL types. The template (mould) is always made individually, according to the customer’s technical drawing, which allows the machine to be fully adapted to the specific pallet specifications.

2. Can I produce different pallets on one table?

Yes. The machine has two independent work stations (on both sides), which allows for the production of two different pallets simultaneously or one large pallet in full synchronisation mode.

3. What is the procedure for starting the machine after a break?

If the break was not caused by an emergency stop, start-up is carried out according to the operating instructions:

- Connect the power supply and compressed air.

- Start the machine with the main button.

- If necessary, perform control tests of the actuators and modules.

4. Can I set the speed and acceleration of the nailing module?

Yes, the operating parameters of the nailing module (speed) can be adjusted from the control panel.

5. How does the pallet counting function work?

The machine automatically counts the number of pallets stacked based on completed production cycles, according to the set programme. The result is visible on the operator display.

6. What are the maximum pallet dimensions and restrictions for other formats?

The maximum dimensions depend on the specific machine configuration.

7. How does the safety system at the table work?

The machine is equipped with safety strips, emergency buttons and position sensors. In case of contact with the operator or an obstacle, the machine stops immediately. The system complies with CE standards.

8. Is one operator sufficient to operate the machine?

Yes, in the standard configuration, one operator is sufficient to operate the machine. However, for maximum efficiency, two people are recommended (for pallet input and output).

9. How many pallets can I produce per day?

With two operators, it is possible to produce up to 500 pallets per day (for the EUR/EPAL format), depending on the work organisation and type of pallet.

10. Is the machine suitable for the production of disposable, industrial and EUR pallets?

Yes, the machine can be configured to produce all types of pallets, from the simplest disposable pallets to certified EUR/EPAL pallets.

11. How does the machine handle boards of varying quality (knots, curvature)?

The machine stops automatically if it detects a problem with nail driving (e.g. on a knot), which prevents damage and material loss.

12. What is the delivery time for the AT-3000 machine?

The standard delivery time is approximately 2 months from the date of order placement.

13. Is installation included in the price?

No. The cost of installation and training is calculated separately and depends on the customer’s location.

14. How long does installation and training take?

Installation and operator training takes an average of 4 hours.

15. What is the service and warranty like?

The machine is covered by a 12-month warranty. After installing the SIM card in the controller, remote service (diagnostics and online support) is available.

16. Do you offer remote support in case of failure?

Yes, we offer remote technical support – via the internet or by phone.

17. How much does the AT-3000 machine cost?

For an individual quote, please contact us using the enquiry form on our website.

18. What are the operating costs of the machine?

The basic costs are: electricity (400V), compressed air, nails and periodic servicing.

19. Do I need an additional compressor or infrastructure?

Yes. The machine requires access to compressed air with a capacity of at least 1000 l/min and a 400V power supply. Details are agreed individually.

20. How does the AT-3000 differ from other pallet machines?

The AT-3000 is a compact, fast and flexible machine that stands out thanks to:

- low air consumption,

- easy template change,

- simple operation and quick operator training,

- optional integration with robots

21. How does it compare to Pneumatico PT machines?

Compared to Pneumatico PT machines, the AT-3000 offers higher automation and the ability to operate in automatic mode, which translates into higher productivity.

22. Why choose the AT-3000 instead of a semi-automatic machine?

The AT-3000 reduces physical work for the operator, increases safety and production repeatability. Thanks to automated assembly, we save time and minimise human error.

23. Is it possible to adapt the machine to non-standard requirements?

Of course. We are able to tailor the solution to unusual requirements – just send us a technical drawing and your expectations.