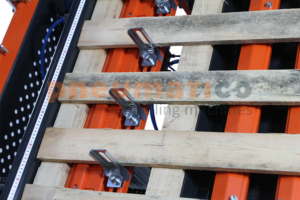

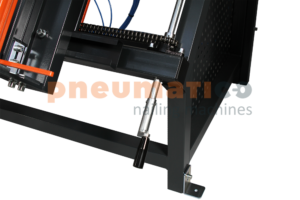

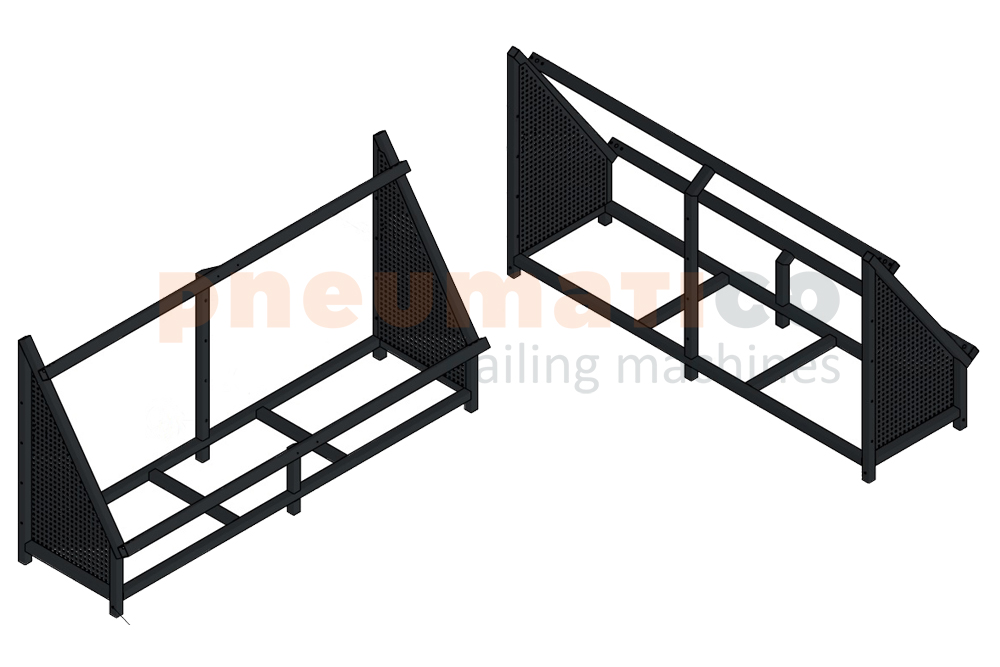

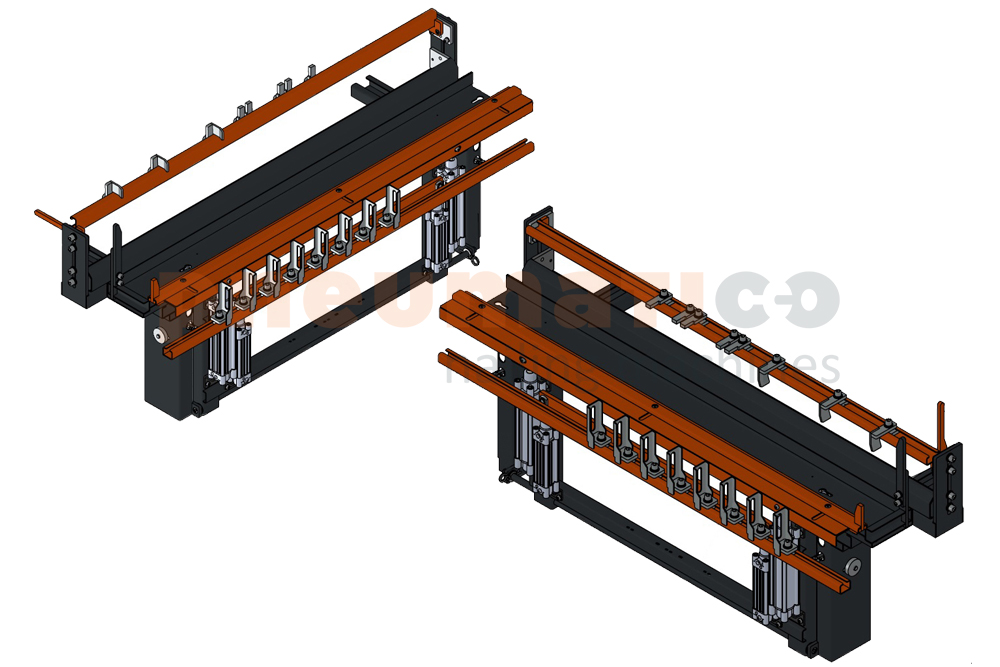

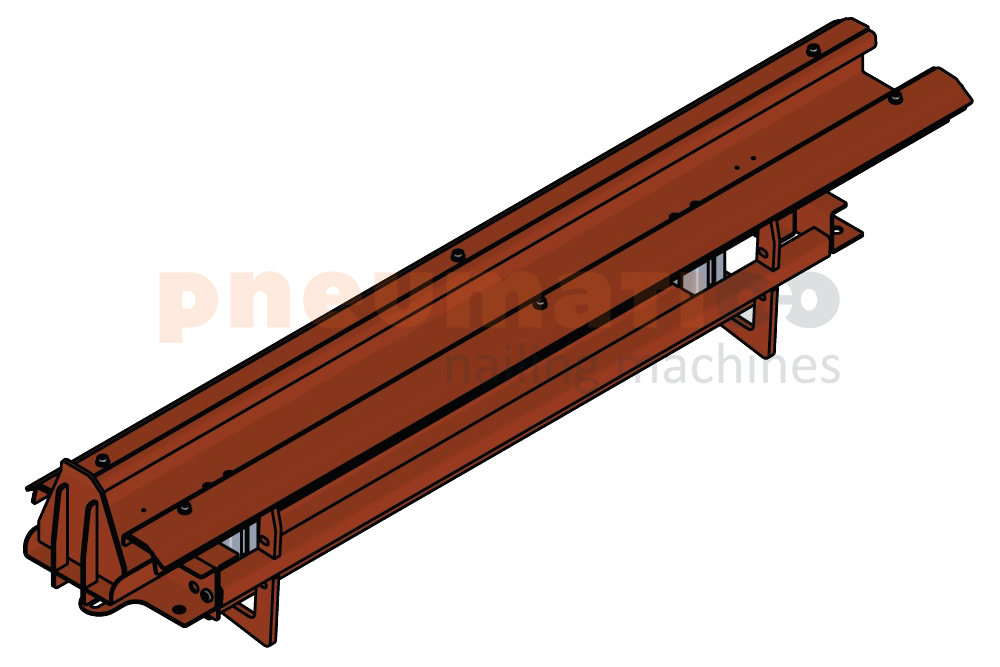

A universal pneumatic nailing table, Pneumatico PT-3300 features an adjustable working top, pneumatic clamping of support elements (blocks or stringers), and pneumatic lift of the pallet towards the operator.

Pneumatico PT-3300 is an adjustable, semiautomatic pallet nailing table for pallets of different sizes. Its ergonomic construction allows fast and easy adjustment of the pallet template size. Widths may vary 900 – 3300 mm and the table supports lengths up to a maximum of 1500 mm. Only one operator is required to produce 170 – 200 pallets during a single 8 hour work shift.

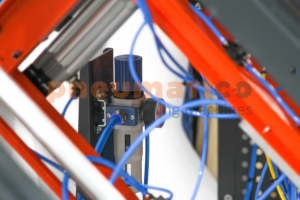

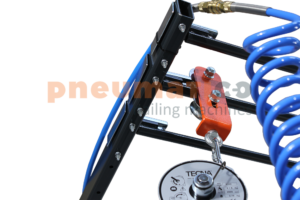

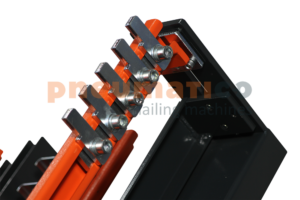

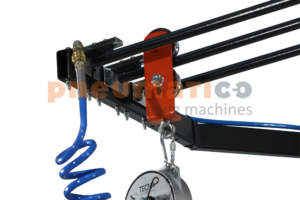

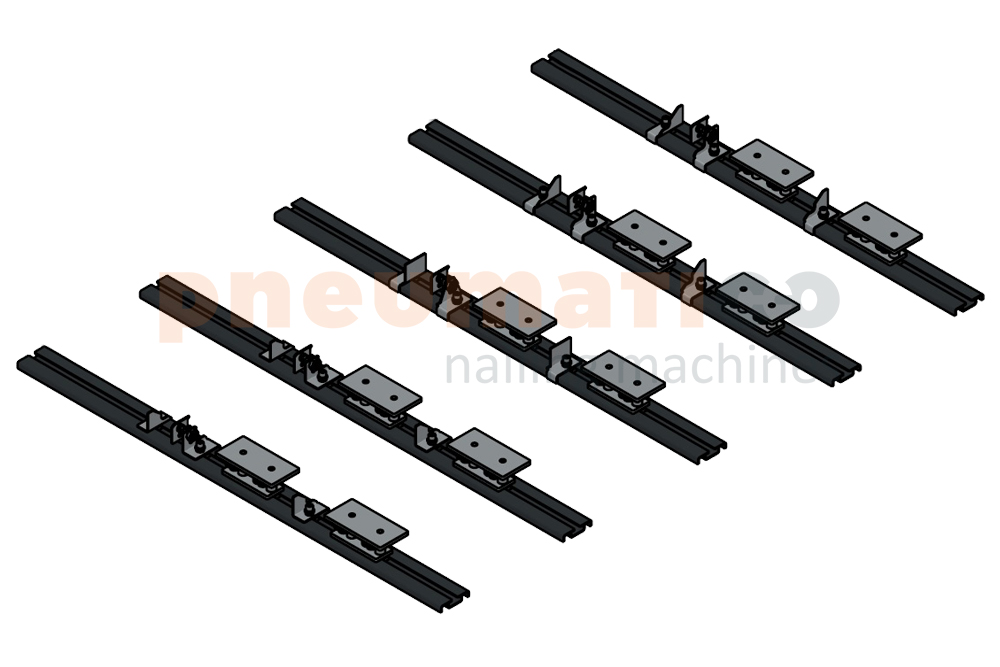

The operator uses multiple nail guns for different sizes of nails. Each of the nail guns is suspended on an overhead roller track for operator convenience. The roller track allows the nail guns to move freely along the rail mounting system overhead. The design of the table guarantees production efficiency as well as operator’s comfort.

Technical specifications:

- Weight: 620 kg

- Operating pressure: up to 8 bar

- Material: structural steel

Dimensions of the pallets:

- Width: 900 – 3300 mm

- Length: 1500 mm

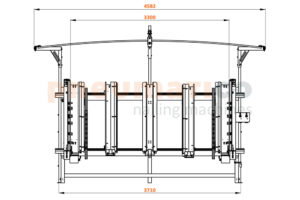

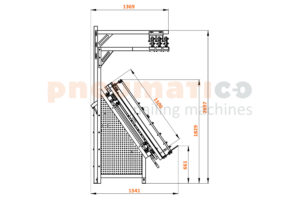

External dimensions:

- Worktop width: 3710 mm

- Table width comprising rail mounting system for balancers: 4582 mm

- Worktop height: 1829 mm

- Table height comprising rail mounting system for balancers: 2697 mm

Certified industrial design: 015022247-0003

Basic equipment

PT-3300 BASIC

1

2

3 i 9

4 i 5

6

13

5

Additional equipment

8

7

6 i 18

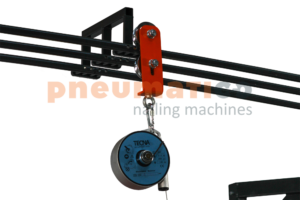

Balancer TECNA 9321

Balancer TECNA 9322

Gwoździarka Stanley Bostitch N80CB-1

Gwoździarka Stanley Bostitch N58C-1-E

Spiral polyurethane hose with fittings

Pneumatic grip for nailer

PU Spiral Tube for TECNA Balancers

Balancer TECNA 9321

Technical specifications:

- Load bearing capacity: 2 – 4 kg

- Rope length: 2,0 m

Description:

- Cast aluminium body

- Stainless steel rope

- Adjustable capacity by means of a knob

- Rubber stroke limiter

- Coated with antifriction material

- Polyamides thimble preventing hook friction

Balancer TECNA 9322

Technical specifications:

- Load bearing capacity: 4 – 6 kg

- Rope length: 2,0 m

Description

- Cast aluminium body

- Stainless steel rope

- Adjustable capacity by means of a knob

- Rubber stroke limiter

- Rope coated with antifriction material

- Polyamides thimble preventing hook friction

Gwoździarka Stanley Bostitch N80CB-1

Technical specifications:

- Tool weight: 3,87 kg

- Operating pressure: 5 – 7 bar

- Air consumption: 1,9 l/ shot

- Magazine capacity: 250 – 300 nails

Dedicated nails:

- Nails length: 38 – 80 mm

- Nails diameter: 2,5 – 3,3 mm

Gwoździarka Stanley Bostitch N58C-1-E

Technical specifications:

- Tool weight: 2,68 kg

- Operating pressure: 5 – 7 bar

- Air consumption: 1,0 l/ shot

- Magazine capacity: 300 – 350 nails

Dedicated nails:

- Nails length: 25 – 55 mm

- Nails diameter: 2,03 – 2,5 mm

PU Spiral Tube for TECNA Balancers

P931X and P932X are kits exclusively designed to feed the suspended pneumatic tools with compressed air. The material is light and ergonomic. The rope is placed inside the spiral tube. The grips might be installed to both old and new TECNA balancers without any interference in its internal housing.

Kit P931X includes:

• Polyurethane spiral tube without fitting

• A set of steel galvanized grips

• One straight plug nipple 10 x 6,5 mm ¼” external thread

• One angular rotary plug nipple 10 x 6,5 mm ¼” external thread

• One male Quickcoupling ¼” internal thread

• One female Quickcoupling ¼” internal thread

Kit P931X fits:

• TECNA 9311, 9312, 9313

Kit P932X includes:

• Polyurethane spiral tube without fitting

• A set of steel galvanized grips

• One straight plug nipple 12 x 8 mm ¼” external thread

• One angular rotary plug nipple 12 x 8 mm ¼” external thread

• One male Quickcoupling ¼” internal thread

• One female Quickcoupling ¼” internal thread

Kit P932X fits:

• TECNA 9320, 9321, 9322, 9323

• TECNA Light 4, Light 6, Light 8

We offer a standard kit that includes:

- Pneumatico PT-3300 table together with pneumatic accessories, i.e. valves, actuators

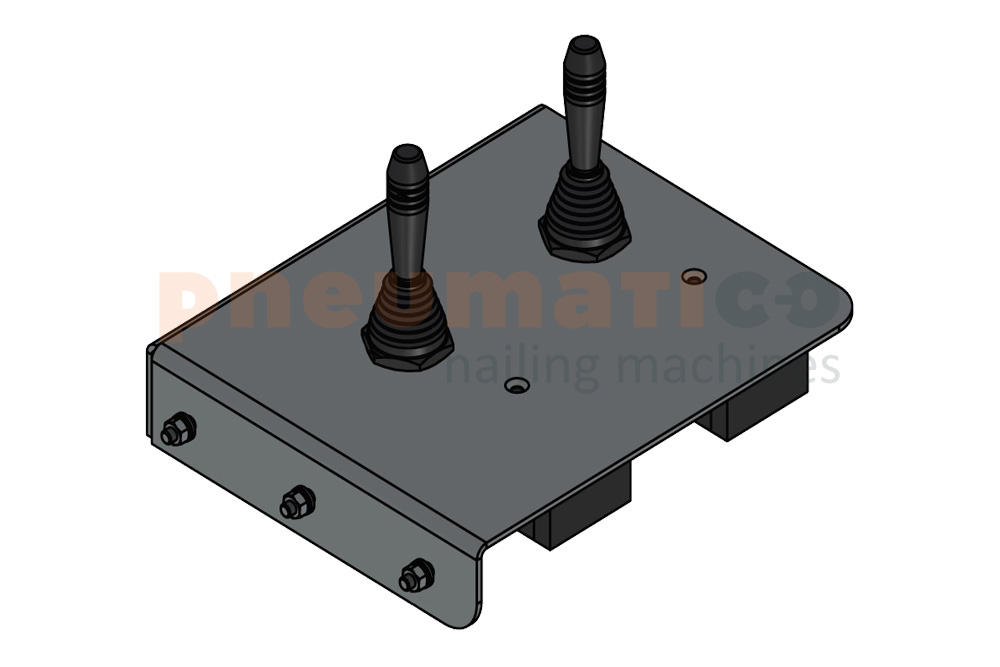

- 2 Control levers

- Central air regulator

- 2 FLR Air units (Filter Regulator Lubricator. Possibility to set different pressure for each nailer)

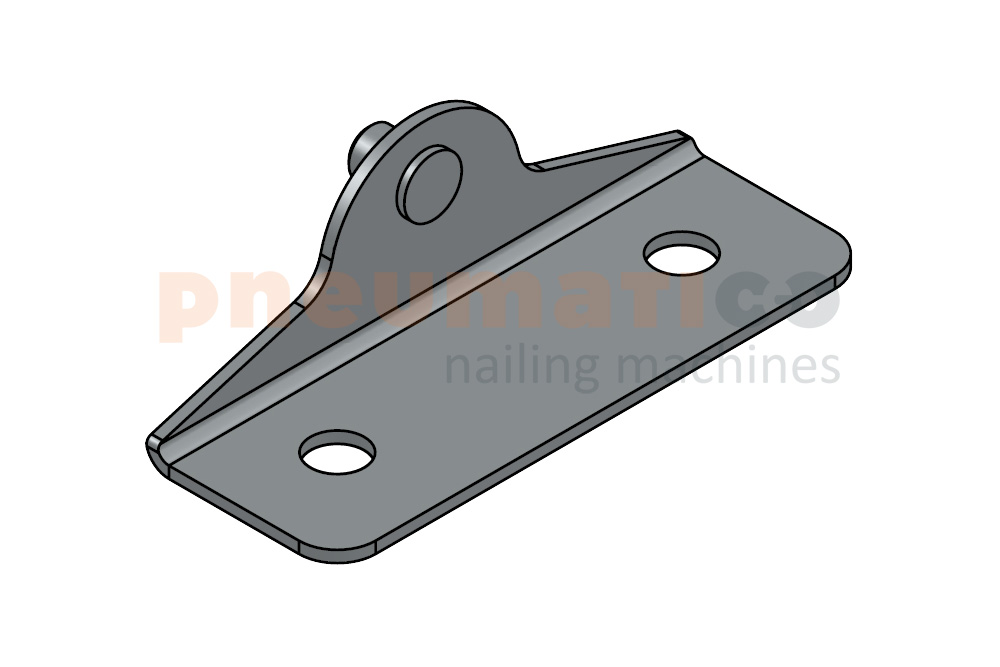

- 6 Anvils to bend AN6 nails

- 3 Templates to produce “ bottoms” of P9 pallets

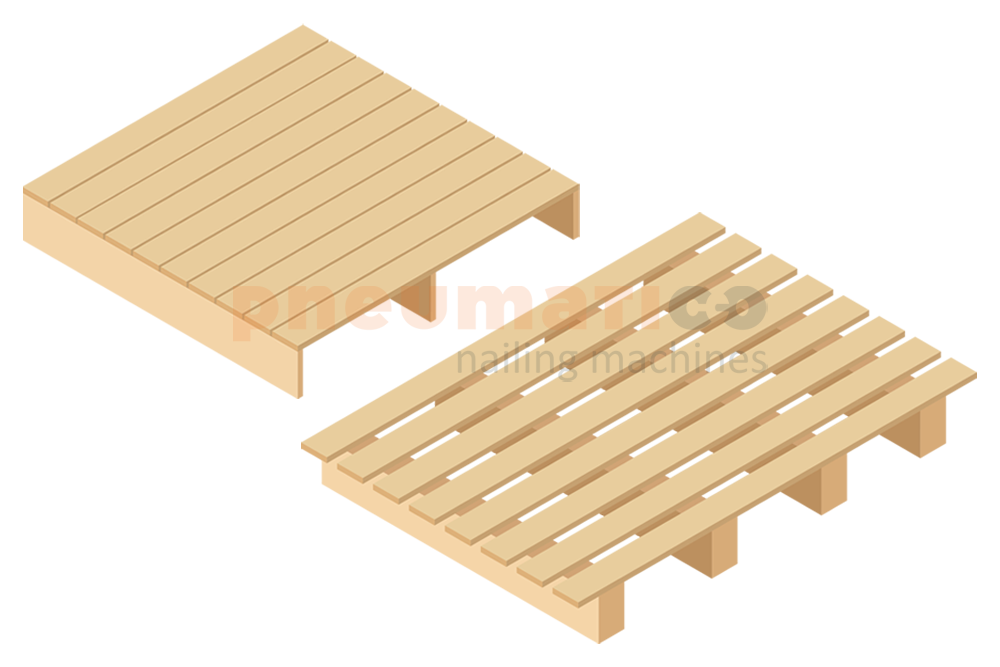

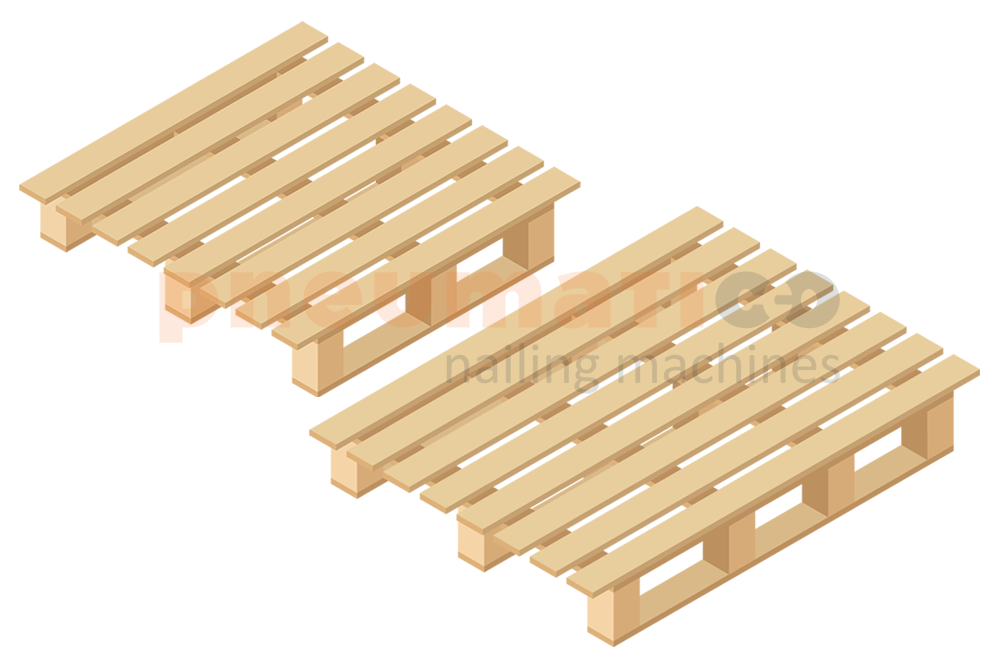

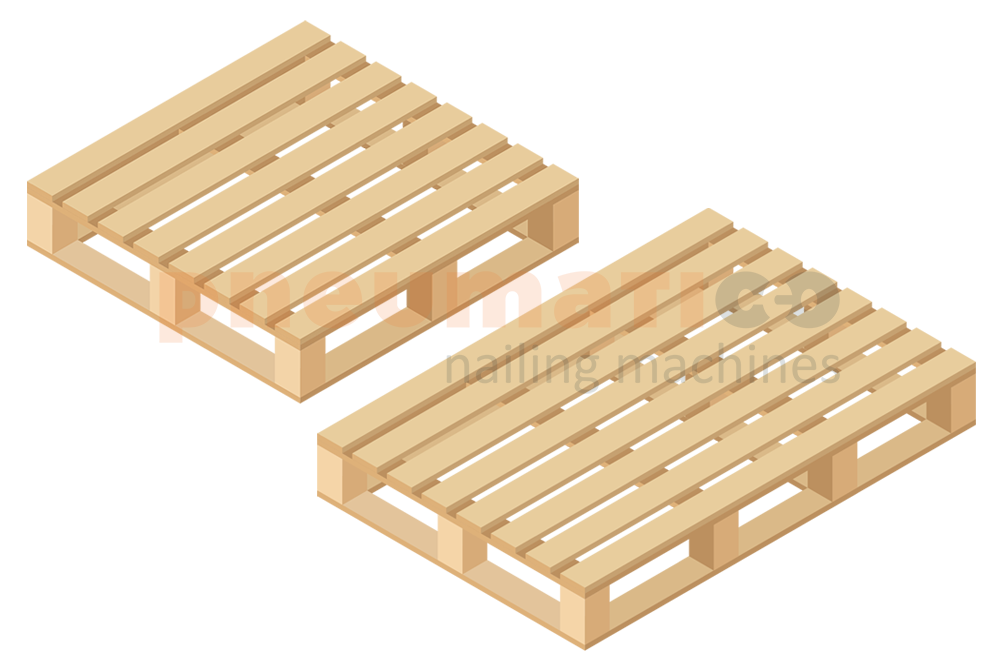

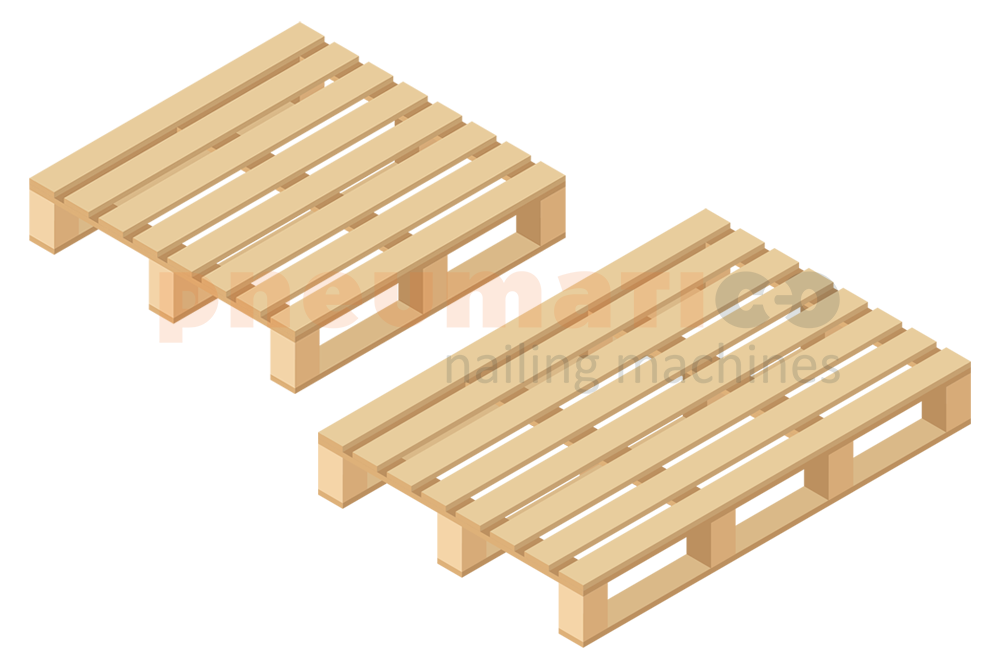

Examples of pallet types that can be produced with Pneumatico PT-3300:

two way entry - wing type

two way entry - reversible

two way entry - close boarded, no base board

four way entry - wing type

four way entry - perimeter base

four way entry - open boarded, 3 base

four way entry - close boarded, perimeter base

four way entry - close boarded, 3 base

1200 x 800 mm

600 x 800 mm

| Easy to use | One operator can build 170-200 pallets within 8 hours |

| Compact design | Total footprint 5.37 m² (57.80 ft²) |

| Universal | Adjustable worktop allows production of:

|

| Efficient | Quickly switch to any size pallet |

| Pneumatic clamp | Easily centers the blocks |

| Pneumatic lift | Raises pallet to minimize operator lifting |

| Overhead roller track | Nail guns can move freely during work |

| Bottom template | Template to build pallet legs |

| Adjustable steel clinch plates | Galvanized and hardened steel plates for clinching nails |

| Unique |

|

| Certified industrial design | 015022247-0003 |

QUESTIONS AND ANSWERS ABOUT THE PNEUMATICO PT-3300

1. How many pallets per day can be realistically built using the PT-3300, taking into account an average worker?

The machine can produce 170–200 pallets per shift (8 hours). The actual output depends on the work organisation and the operator’s experience, but even beginners can achieve over 160 pallets per day.

2. What types of pallets can be produced on this table – only EUR/EPAL, or also industrial and non-standard pallets?

You can produce block and stringer pallets, including EUR, CP1–CP5, industrial and non-standard pallets, up to 1300 mm long and 1000 mm to 1900 mm wide.

3. How long does it take to switch the machine to a different type of pallet?

Thanks to adjustable templates and a quick format change system – a maximum of 10–15 minutes. All you need are two Allen keys.

4. What ergonomic solutions have been used to ensure that the operator can work comfortably throughout the entire shift?

The machine has pneumatic pallet lifting, a nail gun balancing system, upper guides, stops and an optimal working height. Thanks to the appropriate angle of the machine, it significantly reduces strain on the operator’s spine and arms.

5. How does the pneumatic pallet lift work and how does it help the operator?

The lift raises the pallet after assembly, so the operator does not have to remove it from the template manually.

6. Does the operator have to bend or turn unergonomically during work?

No. All key components are within easy reach, and the guide system with balancers ensures full mobility of the nailer without the need for excessive movements.

7. How important is the upper guide with balancers for the comfort of working with nailers?

The balancers support the weight of the tool so that the operator’s hand is not overloaded. This reduces fatigue and improves precision and work speed.

8. Are nailers and balancers included in the set or do they have to be purchased separately?

The machine includes basic pneumatic components, while nailers and balancers are available as optional extras (e.g. Stanley Bostitch IC60-1, N80CB-1, Tecna balancers).

9. Is it worth ordering additional stringer and bottom profiles right away – when are they useful?

Yes, especially if you plan to produce different types of pallets.

10. Do steel clinch plates really improve the quality of nail fastening?

Yes – steel, hardened plates ensure that nails are effectively bent and wedged, which increases the rigidity of the structure and the durability of the pallets.

11. Can the table be retrofitted with a system for building small pallets?

Yes – we offer a set of additional profiles for small pallets as an option. They enable the production of non-standard formats.

12. What is the ‘pallet leg unit’ option and who will find it most useful?

It is a module for assembling pallets with pre-assembled legs. It saves time, especially in the mass production of pallets from ready-made components.

13. How much does it cost to transport the PT-3300 machine to my country/city?

Transport is priced individually, based on the delivery address.

14. Is the machine assembled on site or does it arrive ready for use?

The machine is almost ready for operation. The parts that need to be assembled take about an hour.

15. How much time is needed to start up the machine and for initial training?

A trained operator only needs 60 minutes of instruction. We recommend 2–4 hours of training for new users – we offer online or on-site support.

16. Does the machine need to be mounted to the floor?

No. The machine stands stably on its own steel frame. All you need is a level industrial floor.

17. Do you offer warranty and post-warranty service?

Yes. We offer a 12-month warranty and ensure the availability of spare parts and technical support.

18. Is it possible to produce pallets with offset boards?

Yes.

19. Can the PT-3300 machine produce pallets on blocks?

Yes.

20. How are the blocks positioned on the machine?

The blocks are clamped by pneumatic elements.

21. Is it easy to change the width of the pallet being produced?

Yes. The entire machine can be adjusted using two Allen keys and a crank handle.

22. Do you have a video showing the machine in operation?

Yes, of course. Below are videos of the machine in operation at our customers’ premises, which we are adding gradually.

23. How do you deliver the machine to the customer?

The machine is delivered 80% assembled and securely packaged.

24. Why do you say that this is a premium machine?

The machine is very carefully made – some parts are powder coated, others are galvanised, and the whole thing is made of thick, solid steel.